| Technical Specifications | M2 | M3 |

|---|---|---|

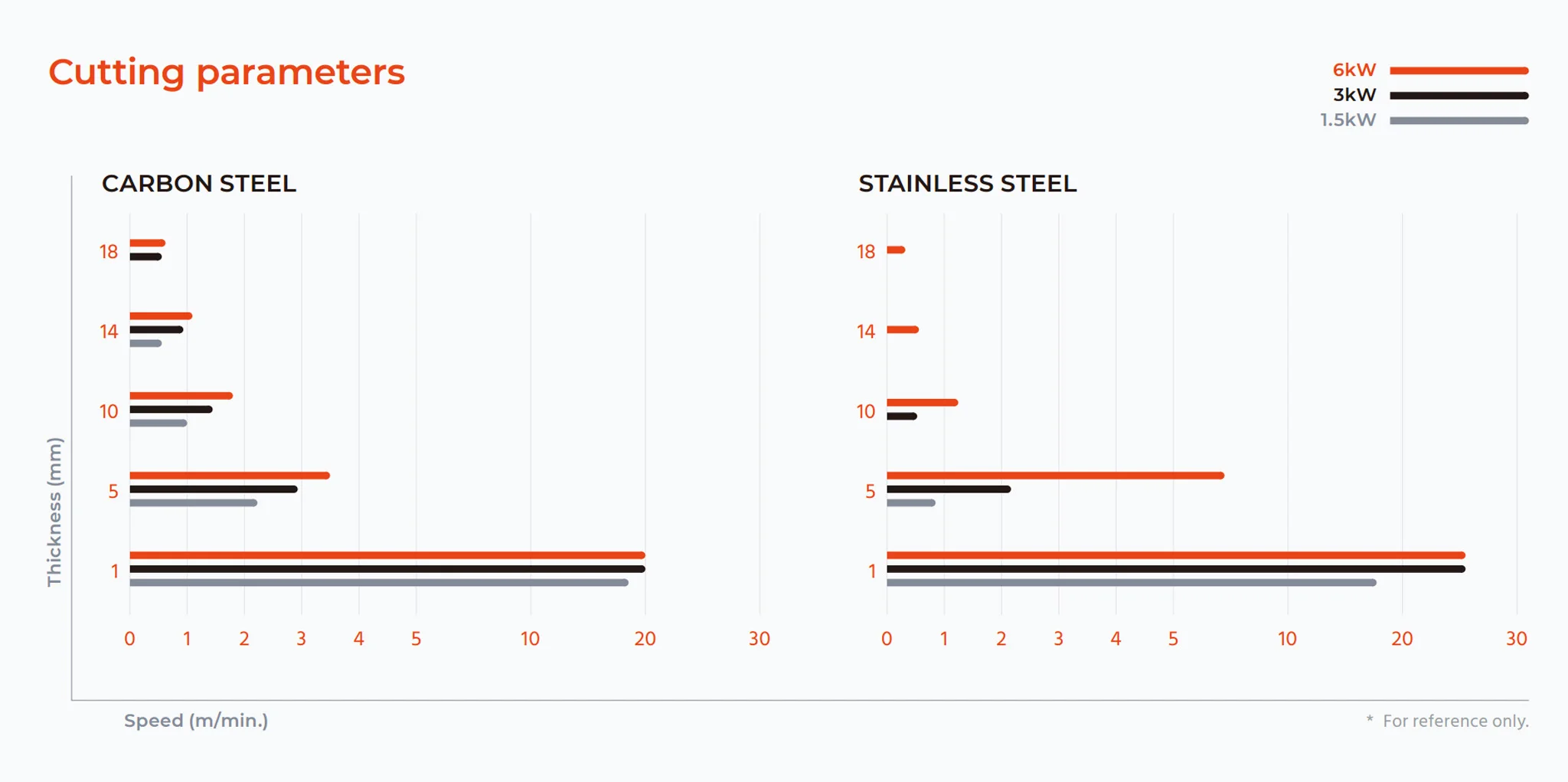

| Laser Power | 1.5/3/6kW | 3/6kW |

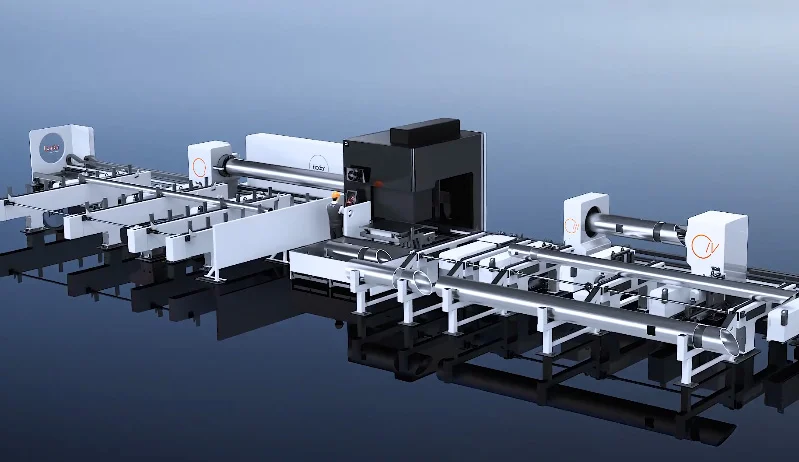

| Tube Size Range | 8-230mm | 25-356mm |

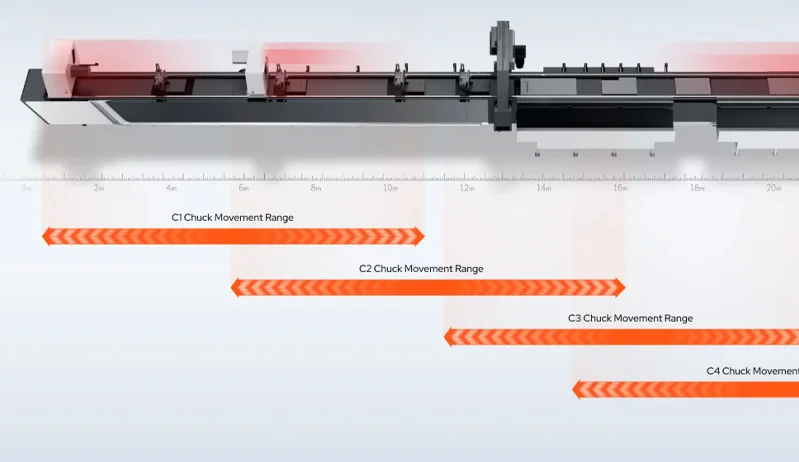

| Max Tube Length | 6500mm | 6500/9200/12000mm |

| Max Tube Weight | 300kg | 800kg |

| X/Y Axis Positioning Accuracy | 0.06mm/m | 0.06mm/m |

| X/Y Axis Repositioning Accuracy | 0.04mm | 0.04mm |

Synchronous Processing

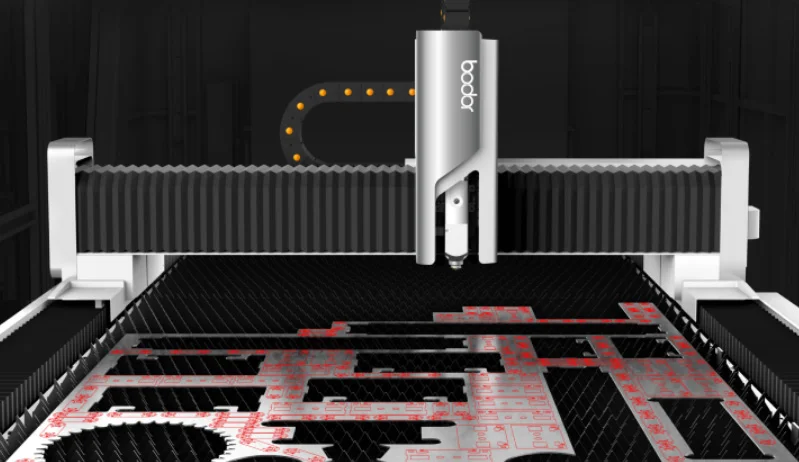

Flexible Cutting Diameters

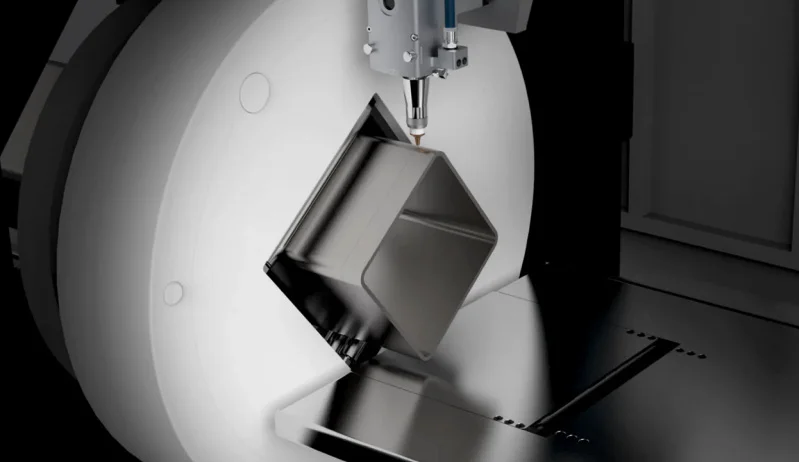

Active Obstacle Avoidance

Weld Seam ID (Optional)

Smart Cutting Modes

IoT Service Ecosystem